EQUIPMENT SALES & SERVICE

Gantry CNC Shot Peen

and Grit Blast

Our custom gantry catalog.

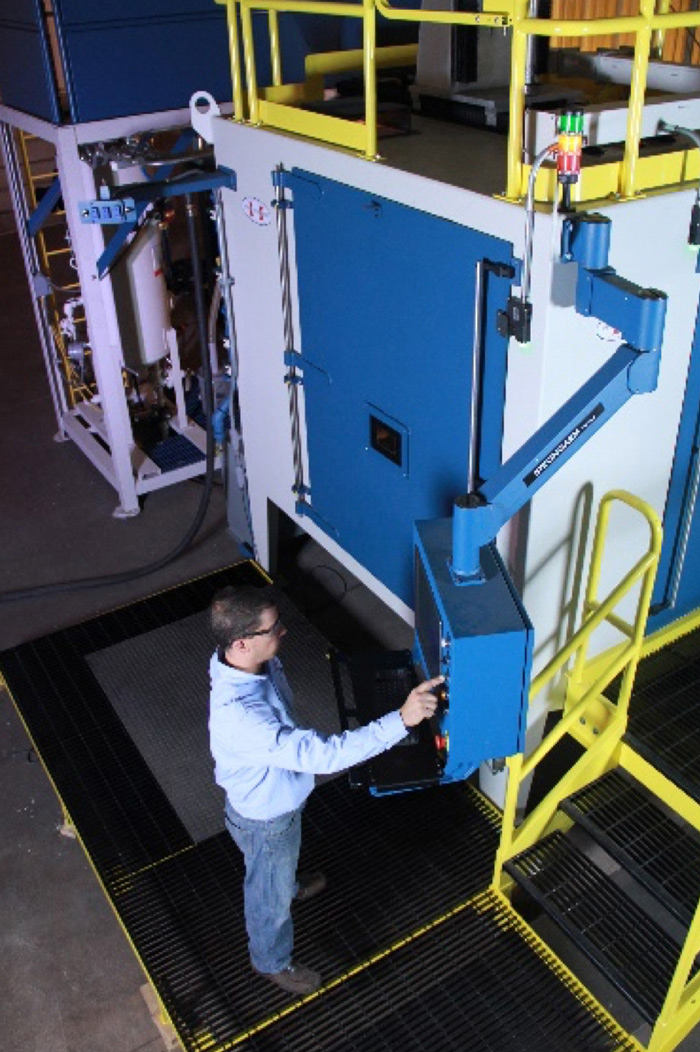

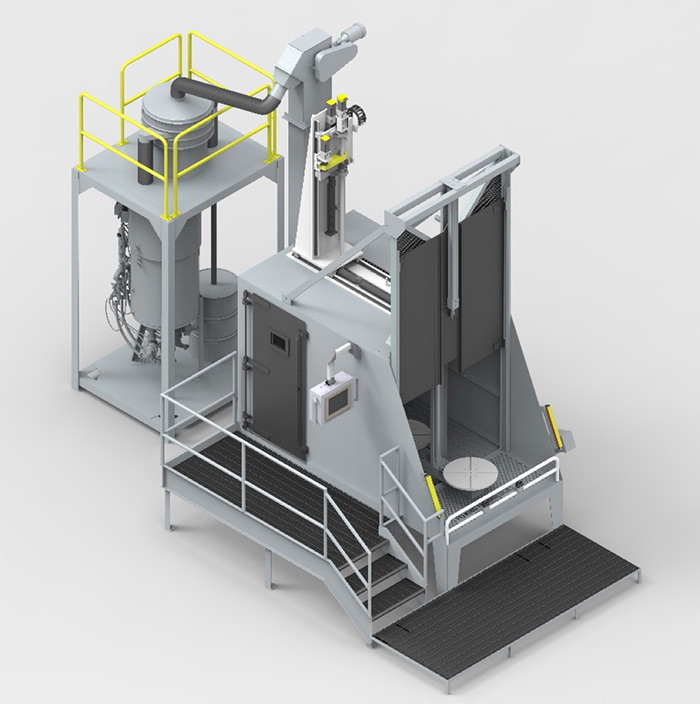

Model PTE-280-G-C CNC Shot Peen

A versatile CNC shot peening machine with 4-axis gantry robot, fully programmable spindle, roller drive, horizontal ID lance, dual media direct pressure system with MagnaValves® and servo air pressure control, drawbridge load door, and optional jib crane.

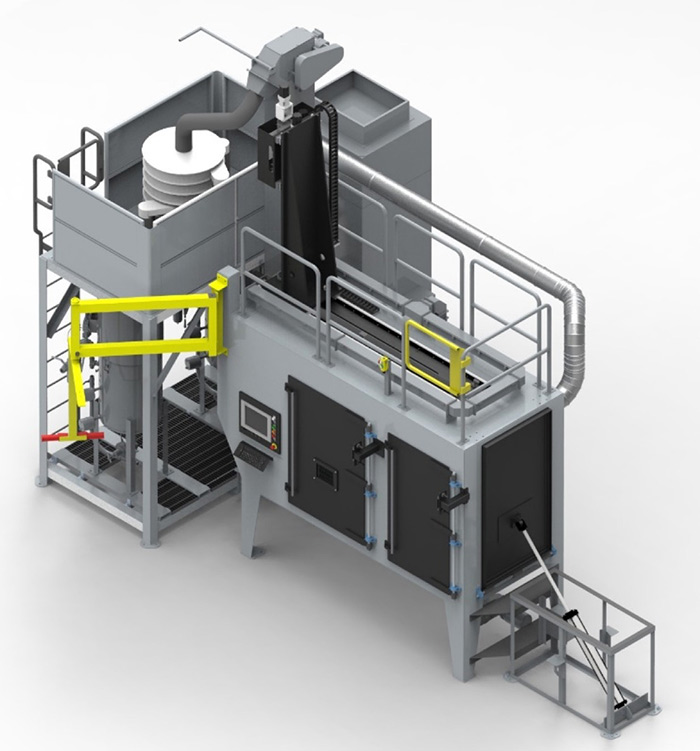

Model PTE-147-G-C CNC Grit Blast

A CNC controlled 4-axis gantry robot with a fully programmable spindle. Single nozzle direct pressure blast system. Vacuum reclaim with cyclone, screen classifier, and auto load hopper. Shown with optional jib crane.

Model 356-G-C CNC Shot Peen

A shot peening machine designed for high volume applications that require the precise control afforded by CNC. Includes a 4-axis gantry robot, a direct pressure system with 3 peening nozzles that operate simultaneously, MagnaValves®, servo air pressure control, dual indexing shuttles, 12 total spindles, custom programming station, and custom operator station.

Model 613-G-C CNC Grit Blast

A CNC controlled 4-axis gantry robot with a fully programmable spindle, a direct pressure system with 3 peening nozzles that operate simultaneously along with a suction nozzle option (for delicate blasting), and custom ergonomic height adjustable operator station. Vacuum reclaim with cyclone, screen classifier, and auto load hopper. Shown with optional jib crane.

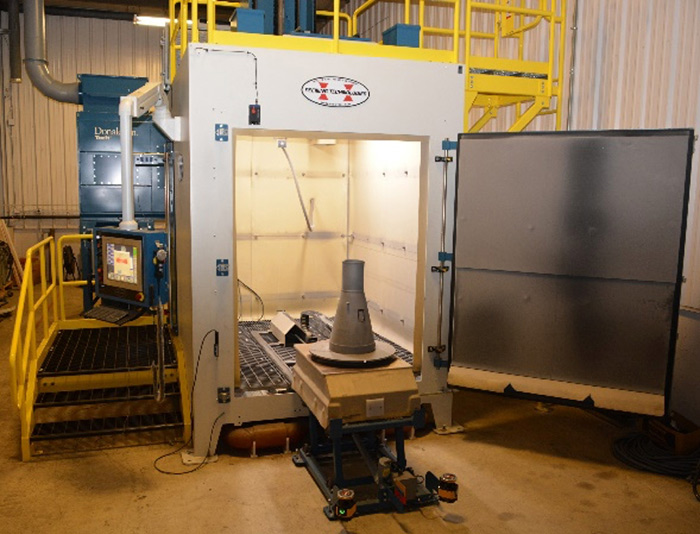

Model 356-G-C CNC Grit Blast

A large capacity CNC controlled grit blasting machine with 4-axis gantry robot with a fully programmable spindle, and single nozzle direct pressure system. Vacuum reclaim with cyclone, screen classifier, and auto load hopper. Spindle platform extends fully for easy part loading.

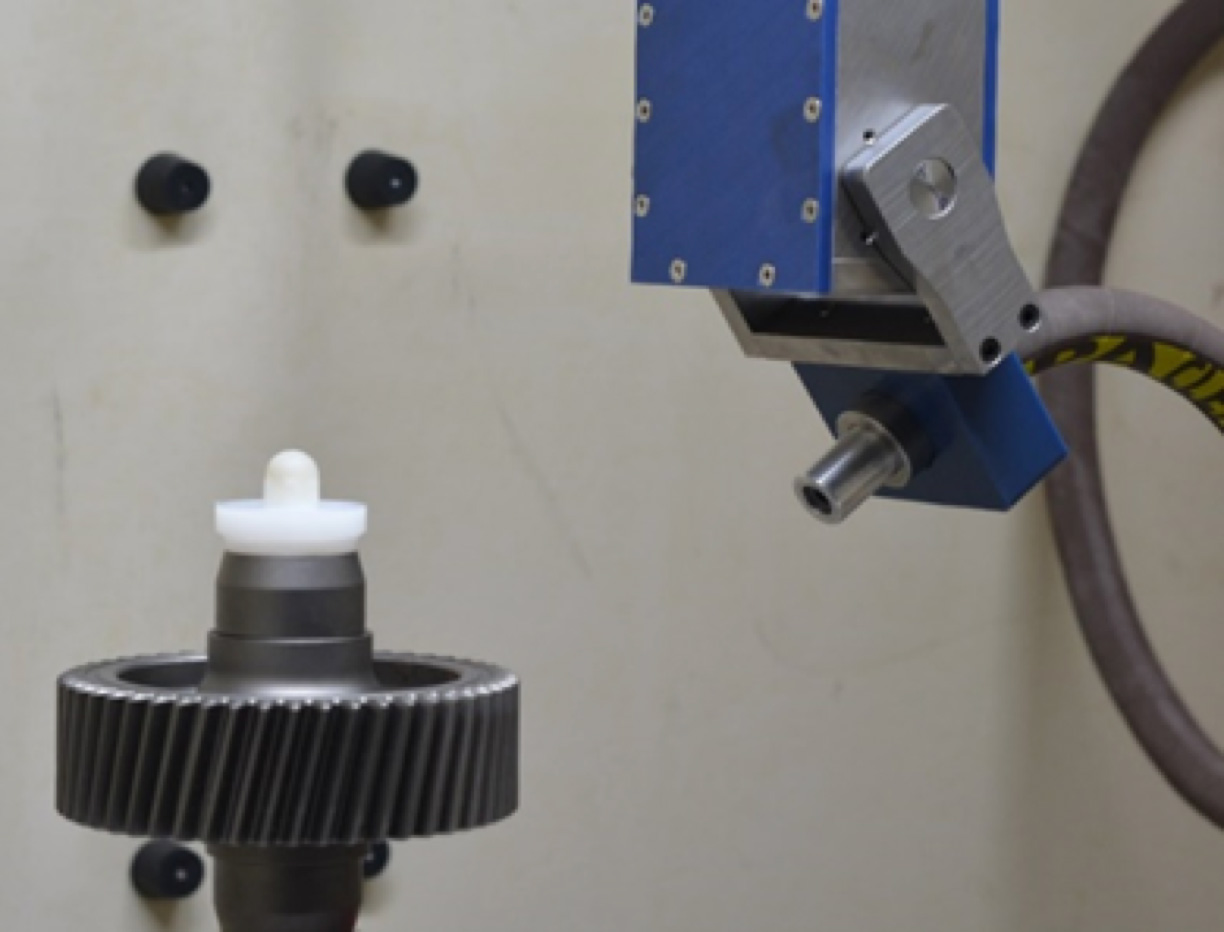

Model 313-G-C CNC Shot Peen

4-axis gantry robot, dual spindles, direct pressure system with 3 peening nozzles that operate simultaneously, MagnaValves® and servo air pressure control. Spindles are fully programmable and allow the operator to load parts while the machine is running.

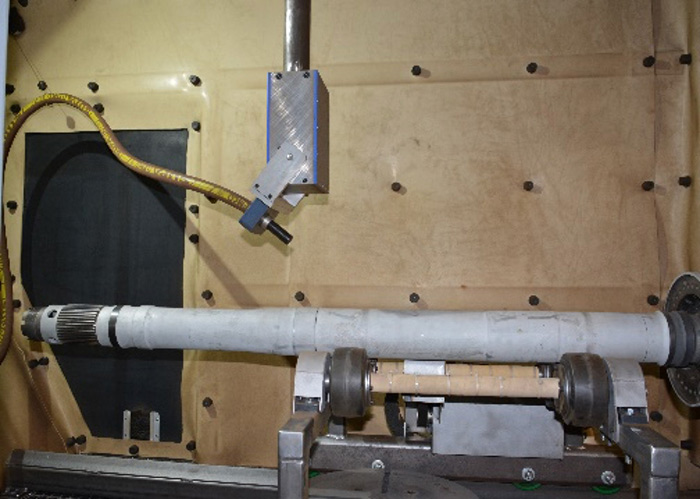

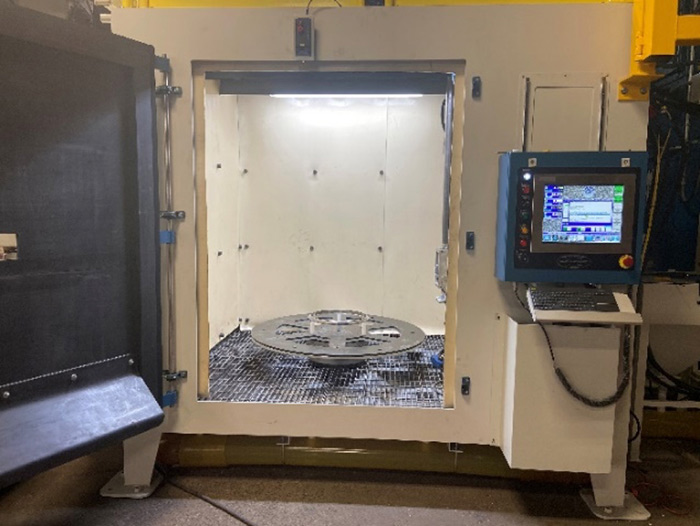

Model 328-G-C CNC Shot Peen

CNC shot peening machine with 4-axis gantry robot and fully programmable spindle. Dual media direct pressure system with MagnaValves® and servo air pressure control. Spindle moves out of the cabinet for easy loading of parts.