Equipment Sales & Service

Tooling & Fixtures

A Patented Process

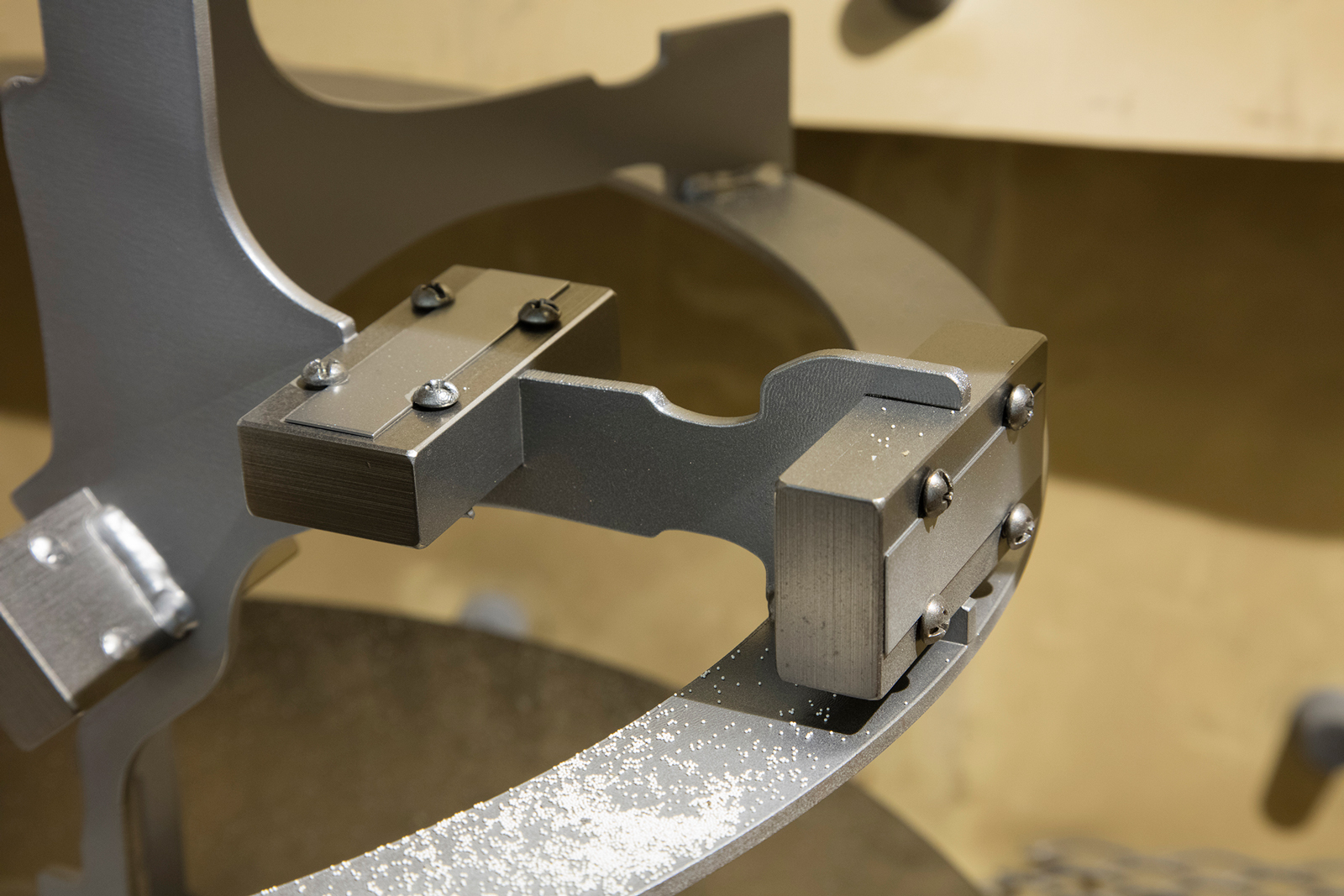

Peening Technologies has patented a process for producing Almen fixtures utilizing 3D modeling called “Apparatus and Method for Quantifying Metal Surface Treatment” (Patent Number US 9,063,049 B2).

We can make fixtures quickly, efficiently, and at a lower price point. Typical Almen fixtures—at least, accurate ones—often require a lot of expensive machining along with long lead times. Scrap parts make nice Almen fixtures but are not often available and they can be expensive to convert.

Most specifications require Almen strips to be placed in locations representing the surfaces requiring intensity verification. However, these specifications offer very little guidance on how to obtain accurate verification data. As a result, Almen fixtures can often be no more than rough representations of the part being peened.

Our method allows us to make our fixtures very accurate without pricing ourselves out of business. The first step in Peening Technologies process is to create a computer-generated 3D part model that identifies the location(s) where intensity should be verified. With this information, Almen strip holding blocks are positioned on the model in the 3D computer program and a support structure is designed. This structure is then typically laser cut into a collection of parts. These parts, along with the Almen strip holders, are welded together to create a customized unit.

In-House Capabilities

- Precision CNC machining

- Precision laser cutting

- 3D Printing

- 3D Solid modeling & design

- Welding and fabrication