EQUIPMENT SALES & SERVICE

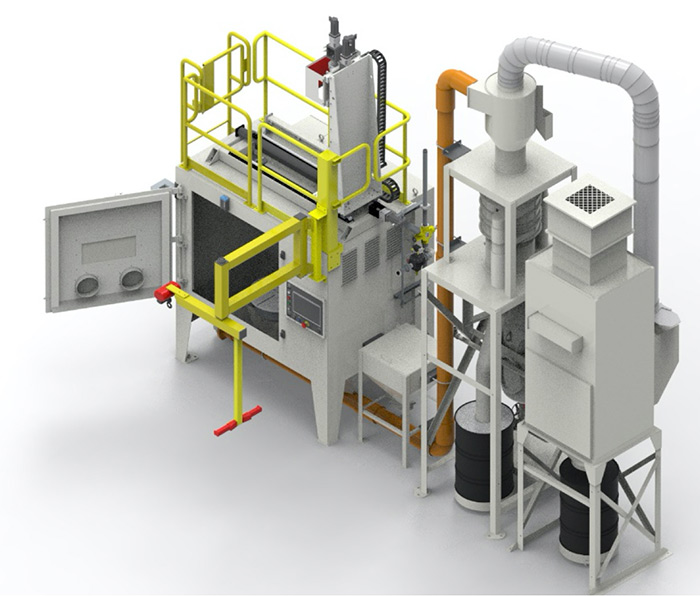

Model PT-170 ABS

This compact abrasive blasting machine includes cabinet, single media system, dust collector, cyclone, classifier, four-axis gantry robot nozzle manipulator and one axis turntable.

Features

Blast Cabinet Enclosure

5’ 6” H x 4’ D x 6’ W (other sizes available). ¼” – ½” A36 steel welded construction. Powder coated finish.

Gantry Robot Nozzle Manipulator

The closed loop-controlled nozzle manipulator is designed to provide programmable coordinated motion in the horizontal (X-Axis), vertical (Z-Axis), rotary wrist (B-Axis), and miter (A-Axis) directions.

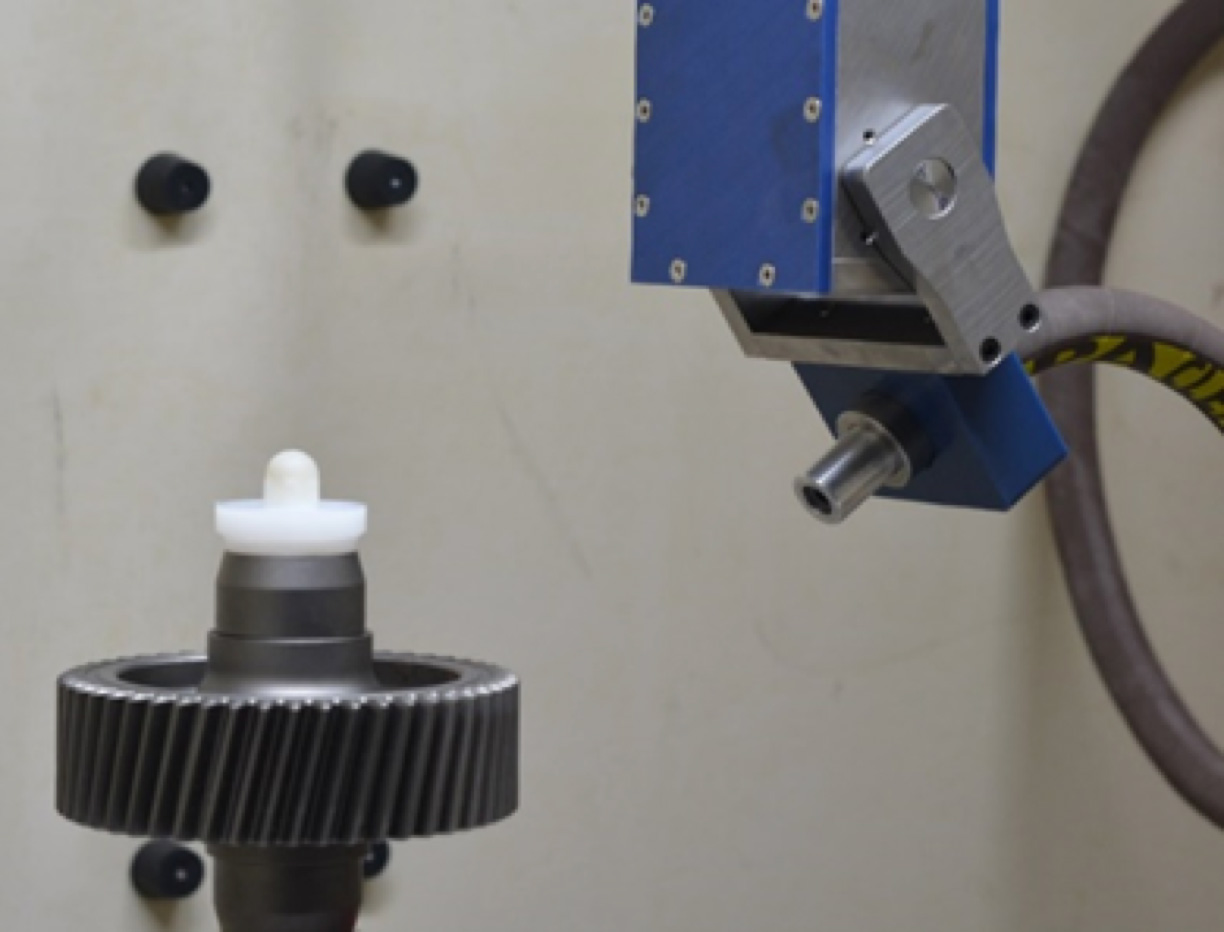

Rotary Turntable

C-Axis is a horizontally mounted table with a 24-inch outside diameter and 250 lb. on center capacity. Programmable C-Axis operated in both indexing mode and spindle rotary mode (depending upon control selected).

Pressure Blast Generator

The abrasive blasting media is fed into the compressed air stream from a six cubic foot capacity pressure vessel. Includes an Electronics, Inc., MFD-P1 Sensor for monitoring of abrasive media flow, a Proportion-Air air volume booster with electronic air pressure regulator for air pressure, and media level sensor.

Media Cleaning and Classification System

A vacuum recovery system pulls media from the bottom of the machine to a cyclone separator where dust and fines are removed. A classifier then screens the media, removing additional fines and oversized media.

Dust Collector System

Compact cartridge style dust collector with auto pulse and HEPA filter.

Auto Load Hopper

Stores abrasive blast media and adds media to the system when low.

Control System Options

Includes FANUC Oi-f, Rockwell Automation PNC, Delta Tau Power Brick (Fall 2022) with each control offering:

- Standard M and G code programming.

- Visual Shot Peening™ – Our graphical interface (HMI) that displays key process variables including motion, air pressure, shot flow, program status, and alarm status.

- Teach Pendant – is included to facilitate programming.

- Process Monitoring – Alarms include machine status such as ‘door open’ or ‘reclaim not on’, HI/LOW shot flow, HI/LOW air pressure, X, Y, A, B, and C axis drive faults including speed, following error and over-travel.

- Optional Data Logging – Machine events are logged to an SQL database for analysis.

Additional Options Include:

- Cabinet mounted jib crane with 250 lb. capacity.

- Optional manual blast station.